The demand for sanitary pumps from various industries is continually growing. This comprehensive guide on sanitary pumps answers essential questions, such as what are sanitary pumps? What are the different types of them currently available in the market? And, how to maintain them?

What Are Sanitary Pumps?

Sanitary pumps are used for the transportation of products and solutions in a variety of commercial industries, including dairy and food processing, agriculture, horticulture, brewery and distillery, pharmaceutical, fine chemicals, food additive, food, cosmetic, etc. These days, they also find significant usage in the field of life sciences and biotechnology, where they are often used to facilitate hygienic mixing, metering, and dilution.

Commonly, sanitary pumps are either made from plastic or metal. Metals, such as copper, bronze, and stainless steel, are the standard metal choices for the construction of them. In terms of plastic, PVC and CPVC are the ideal choices.

The actuation used varies in nature. However, pneumatic, electric, manual, and hydraulic are considered to be the ideal choices for pump actuation. Similar to actuation, the connections also vary in sanitary pumps. Tri-clamp, butt-weld, flange, seamless flange, threaded, and thrust are some of the preferred connection types.

Here Are a Few More Things You Must Need About Sanitary Pumps

These days, sanitary pumps offer several handy features. When it comes to speed specifications, there are two different types of them: adjustable speed pumps and continuous duty pumps. With adjustable speed pumps, the operator can adjust the speed to suit the requirement.

Continuous duty pumps, on the other hand, always wok at 100% duty cycle. Variable speed pumps offer higher reliability and control. However, the vibrations associated with these pumps are often a nuisance. Moreover, the initial cost of installing variable speed pumps is much higher than the initial cost of installing continuous duty pumps.

Operators are usually always advised against running a pump dry as it can damage the pump by melting the shaft and the impeller. However, these days, run dry capable sanitary pumps have become quite common. These pumps can operate without a liquid and do not require any form of external lubrication for a long span.

Lastly, based on their ability to move media, there are two types of sanitary pumps: horizontal sanitary pumps and vertical sanitary pumps. While a horizontal sanitary pump is easier to install and maintain, it supports lower temperatures and working pressures than a vertical pump. Moreover, vertical sanitary pumps require a smaller footprint and can also be used in areas with restricted ground space. Thus, these days, vertical pumps are given preference over horizontal sanitary pumps.

While buying a sanitary pump, users should look for the following specifications: inlet & outlet sizes, body material, flow rate, discharge pressure, media temperature, etc. These specifications directly affect the functionality and efficiency of sanitary pumps. Users also have the option to choose from a variety of power sources, including alternating current, direct current, natural gas, diesel, gasoline, etc. These days, sanitary pumps that do not require any power source are also available. These pumps use a drive shaft to connect to a motor.

What Are the Different Types of Sanitary Pumps?

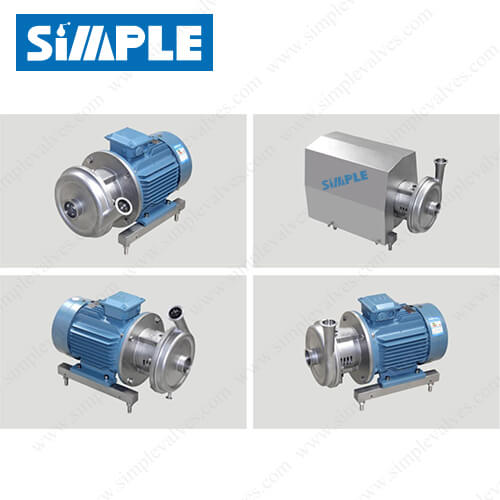

A sanitary pump is an apparatus used to transport organic material to places that engage in food processing operations that require a high grade of cleanliness. There are four different kinds of sanitary pumps each with their own unique design.

- A sanitary centrifugal pump is a pump that works by applying centrifugal force in order to create velocity and then increasing it by use of rotating impellers which causes liquid to be pushed through an outlet valve.

- A sanitary positive displacement pump is a pump that works by the use of gears and rollers to force fluid into a designated space so that when the liquid is present, a vacuum is created that pulls in more liquid.

- A sanitary self priming pump is a centrifugal pump that works by using a mature of art and water to operate.

- A sanitary mixing pump is a pump that is designed to mix both slurry and solid materials.

How to Maintain a Sanitary Pump?

Improper maintenance leads to unwarranted expenses, which hurt the most. Thus, to avoid unexpected maintenance expenses, make sure you are sticking to a pump maintenance checklist. Checking mechanical seals and bearings can help prevent mechanical failures. Seals perform the essential function of separating clean from the dirty.

Any problem with the mechanical shaft seal can cause the pump to stop working. Similarly, a lubrication failure can also damage the pump. Issues related to chemical and physical degradation can also negatively affect the life of a sanitary pump. Thus, it is essential to run customary checks on sanitary pumps from time to time.

Moreover, users should not be dissuaded by the initial cost of a sanitary pump. Sanitary pumps that have a high initial setup cost have a low MTBF (mean time between failures) value. In simpler words, a pump with low MTBF value will last long without needing any repairs.

Thus, the chances of pump failure also become less. It is, thus, that pumps with low MTBF value lead to lower operational costs. It is, therefore, better to invest in these pumps even if their installation is more expensive than the other available options.

The Bottom Line

Sanitary pumps are a necessity in many industries. We hope this comprehensive guide has equipped you with the information you need to make an informed decision about which sanitary pump is the right choice for you.

Our People Want to Help

As a manufacturer of stainless steel sanitary pumps, SIMPLE VALVES aims to arm its potential customers with information that would help them in making an informed decision.

Our sales representatives are ready to help, please feel free to email us at sales@simplevalves.com or submit your request directly in below form.

Leave A Comment