A mix-proof double seat valve is a type of valve that features two separate pipelines for multiple liquids to flow through. Each pipeline has its own seals and seats that can be activated to regulate flow. The empty space between the two lines works as a containment chamber.

But the main purpose of this particular structure is that while the two medium can flow through simultaneously, they do not intermingle and create a contaminated end-product at the outlets.

Sanitary mixproof double seat valves make the whole process involved more efficient without compromising purity. Their spillage-free feature makes these valves especially appropriate for dairy industries and industries that deal with viscous materials.

How It Works

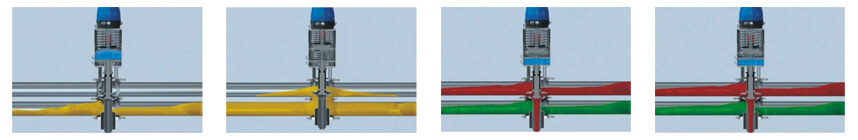

The basic function principle is pretty simple. As mentioned, the separate flow lines have two separate plug seals. The valve actuator mostly functions in the pneumatic method. When the valve is in open state, the atmospheric pressure between the two seals creates a leakage/containment chamber that works as a safeguard against any potential leakage from either of the pipelines. While extremely unlikely, in case of accidental leakage, the liquid will flow into this chamber and out through the leakage outlet instead of spilling into the other pipeline. When the valve is open, the leakage chamber remains closed, and thus maximum purity is ensured.

While not a part of the basic operation, the cleaning system that sanitary mixproof double seat valves generally feature has become standard due to its efficiency. The spiral cleaning system is used to decontaminate surfaces that require regular cleaning without raising the overall cost. The clean spiral medium can cover more surface (leakage chamber and plugs) at a consistent rate with minimal labor. Also, it also doesn’t require any manual association to reach awkward positions. It’s a very effective method to keep surfaces with too few scratches-per-inch or too many bumps and valleys clean and keep them free of contaminants.

Basic Structure

Regardless of valve design, a sanitary mixproof double seat valve is mainly comprised of a body, plugs, actuator, and options for cleaning purposes. In addition, each valve also comes with an assortment of accessories that are specifically purposed for the operation it’s designed to perform.

The construction of these valves purposefully keep flexible to facilitate personal customization. This way, a single valve type can be modified and fitted to support operations that handle liquids with opposing viscosity. In addition, they also feature “Leakage detection holes.” Thanks to these, any damage to the 0-rings can be visually observed without dismounting and disassembling the valve.

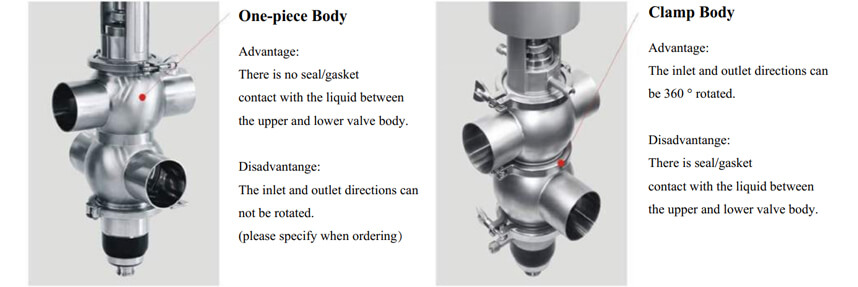

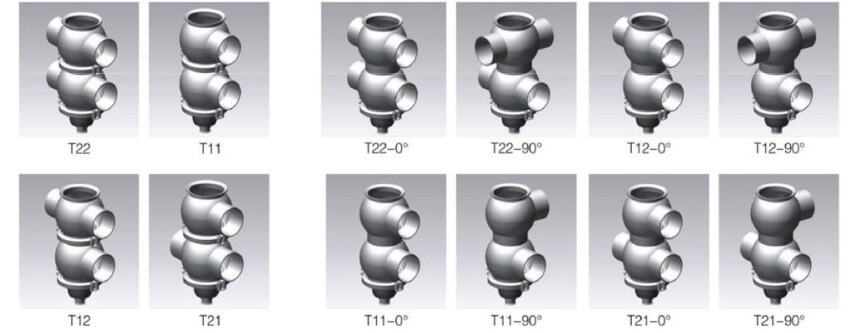

Body Combination

Technical Specifications

Between 1.5 and 4 inches in size

Operated with a pneumatic actuator by default

Compact spherical body (forged)

Operating pressure: between absolute vacuum (minimum) and 145 psi (maximum)

Temperature: works between 14 and 266 degrees Fahrenheit. Can handle up to 284 degrees Fahrenheit for short-time, temporary sterilization.

Air pressure: between 79 and 102 psi (compressed)

R 1/8″ air connections

Releasing the clamp disassembles the structure.

Features of Sanitary Mixproof Double Seat Valves

The individual features of a double sealing valve can explain how it manages to keep the operation sterile while handling a larger sum of process media.

The lock-interface created by air pressure between the two plugs keep the fluids from contamination.

The seal shafts are controlled by an intelligent pneumatic actuator, which protects against switching leakage. This usually occurs just after a seal lifts from its seal and before it reaches its axial seat above the bottom seat.

The inlet and outlet of the valves are designed to facilitate absolute horizontal mounting. It means the tank-valve joints connect with a 0-degree rise or fall. This allows for the handling of floating particles as big as 45 mm without risking particle break and build-up.

The maximum horizontal installation also creates minimum room for “dead areas.” Dead areas, like sumps and domes, are awkward positions that make cleaning a system harder. Their absence, combined with the horizontal mounting, makes the system 100% drainable of process media, including cleaning options. The high cleanliness and sterilization rates make the valves applicable in dairy, beverage, pharmaceutical and biopharmaceutical industries.

Every sealing is free of crevices.

Shaft, seat, leakage chamber, seal, and every other product-wetted parts are made to be 100% comprehensibly cleanable.

Smooth surface, lack of dead areas, and crevices allows for minimum usage of cleaning liquids.

A single sanitary mixproof double seat valve can perform the functions of 2/3 valves of its kind. So, even though they cost more than their counterparts, double seat valves prove to be highly cost-effective in time.

If the lower pipeline is connected with a water hammer, then the pressure from that hammer could lift the lower seal from its seat and cause leakage. Double seat valves with balanced plug eliminate this risk.

Sanitary Mixproof Double Seat Valve Types

Based on the operation and purity requirements, sanitary mixproof double seat valves can be classified into the following categories:

A high alloy sanitary valve is designed to function in situations that require the handling of corrosive materials like low pH or fluids and chemicals with high chloride levels. These valves are especially purposed to perform “tough jobs” within the home care and dairy industries.

Ultra-pure valves are special-purpose valves that are designed to perform within the strict requirements and necessities of the pharmaceutical and biopharmaceutical industries. These are among the most flexible valves since they’re often needed to be repurposed to keep plant function efficient without compromising safety. The high alloy feature can also be integrated into an ultra-pure valve.

A basic sanitary mixproof double seat valve cannot perform in specialized applications like handling corrosive materials. While their leakage detection and safety features are significant, their actuators don’t feature any seat lifts and work on the unbalanced plug principle.

Seat clean valves are designed to be installed in systems that handle liquids with a significant amount of solids. Both the plug and seat are cleaned when the seats lift to perform normal procedures. The balanced plug (lower) principle eliminates the risk of product contamination due to high pressure.

High clean valves are purposed to handle sticky fluids. The clean spiral feature mentioned earlier is best for cleaning its spindles, plugs, and leakage chamber. Applying the balanced principle on the upper and lower plugs eliminates both the effects of water hammer and pressure buildup.

It’s nigh impossible for a sanitary valve to be cleaner than an ultra-clean double seat valve. Their extremely hygienic feature makes them perfect for handling sticky products, fluids with considerable amounts of solids and systems that require near-aseptic status. Integrated seat ‘lift, spiral clean and balanced plugs all complement this ultra cleanliness.

Thanks to their high modification potentials, sanitary mixproof double seat valves can be used in almost any system that requires hygienic and sensitive processing.

Our People Want to Help

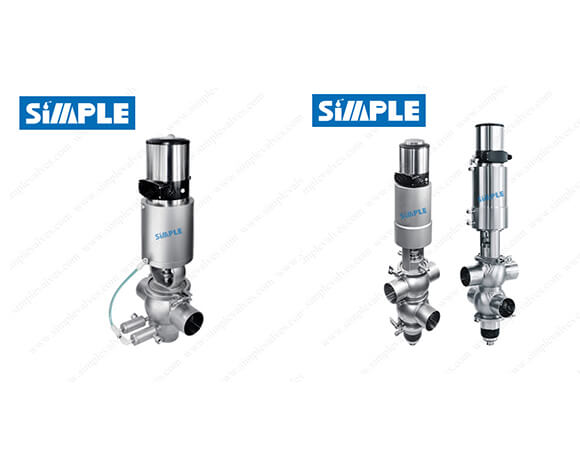

As a manufacturer of stainless steel sanitary valves, SIMPLE VALVES aims to arm its potential customers with information that would help them in making an informed decision.

Our sales representatives are ready to help, please feel free to email us at sales@simplevalves.com or submit your request directly in below form.

Leave A Comment