Hygienic Ball Valves with Tri-clamp Ends, Cavity Filled, Pneumatic Type

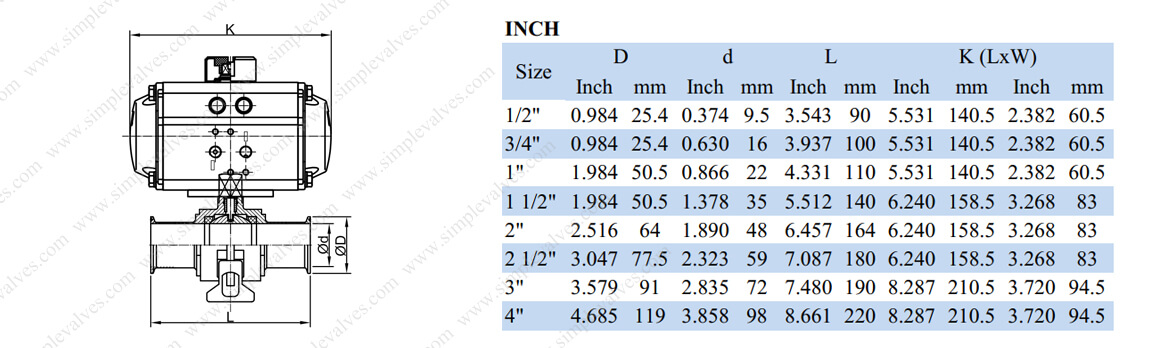

Sizes available: 1/2" to 4", (DN15-DN100)

End connection: tri-clamp / tri-clamp

Body & Disc: AISI 304 or 316L, (EN1.4301/EN1.4404)

Seat: Cavity Filled Teflon (PTFE) + EPDM/VMQ (Silicone)/Viton (FPM) Gaskets, FDA.

Max. working pressure: 145psi (10bar)

Operation: horizontal actuator, aluminum material, AA/NC/NO

Actuator air pressure: 58 ~ 102psi (4 ~7bar)

Temperature range: 14°F ~ 248°F (-10°C ~ 120°C) as default, higher available upon request.

Surface treatment: Ra 32μin (0.8μm) as default, Ra 16μin (0.4μm) as best.

APPLICATION

SV-2PCC series pneumatic hygienic ball valves are also known as non-retention ball valves, they are with horizontal actuator. The valve body with unique design prevents the medium from retaining inside after medium flow. This ball valve is designed for pharmaceutical and biotechnology industries. SV-2PCC series ball valve operates automatically.

TECHNICAL DATA

| Body Material | AISI 304 or 316L (1.4301 / 1.4404) |

| Other Steel Parts | AISI 304 |

| Seat Material | Teflon (PTFE) + Silicone (default) |

| Seat Options | Teflon (PTFE) + EPDM, Teflon (PTFE) + Viton (FPM) |

| Max. Working Pressure | 145psi (10bar) |

| Working Temperature | EPDM: 14 ~ 248°F (-10 ~ 120°C) |

| Silicone: -58 ~ 356°F (-50 ~ +180°C) | |

| Viton (FPM): -22 ~ 428°F (-30 ~ +220°C) | |

| Internal Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default. |

| External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default. |

| End Connections: | butt-welded, sanitary tri-clamp, or others upon request. |

| Pneumatic Actuator Types | Normally Closed (NC) – Air to open and spring to close; Normally Open (NO) – Air to close and spring to open; Air to Air (AA) – Air to open, air to close. |

| Actuator air pressure | 58 ~ 102psi (4 ~ 7bar) |

| Electric Actuator Types | ON/OFF Type Intelligent Modulating Type |

| Units for intelligent control and indication | Proximity Switches (position sensor) Limit Switch C-top control IL-top control (Positioner) |

DESIGN FEATURES

Design Features

● All stainless construction, forged 304 or 316L grade stainless steel body & disc.

● FDA-approved seat materials: EPDM, Silicone, Viton (FPM).

● Sanitary surface finish, available with Ra < 0.4µm or EP (SF1 and SF4)

● Manual handle, pneumatic actuator and electric actuator are interchangeable

● A wide selection of different end connections

● Standards: DIN, 3A, SMS, ISO / IDF, BS / RJT, and ASME / BPE

● Certificates: 3A, FDA, PED 97/23/EC, ISO9001/2008

● Suitable for low and medium viscosity fluids

● 100% hydraulic tested / 100% inspected

● Repair Kits available consisting of seat and bushings

Operations

● Actuators

Pneumatic stainless steel actuator (vertical type)

Pneumatic aluminum actuator (horizontal type)

Electric actuator

● Units for intelligent control and indication:

Proximity Switches (position sensor)

Limit Switch

C-top control

IL-top control (Positioner)

● Handles

Pull handle, three or four positions

Multipositioning handle with plastic cover

Multipositioning handle with stainless steel cover

Lockable multi-position handle