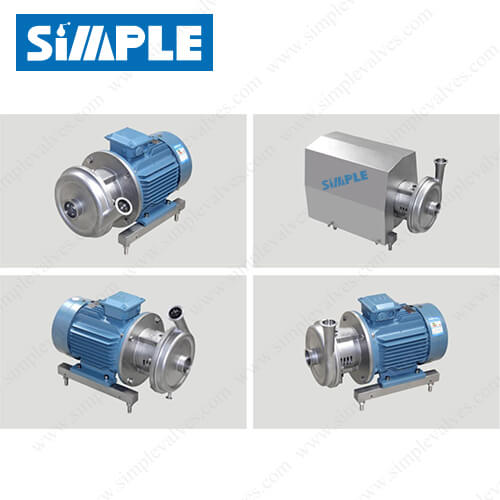

Sanitary Mixing Pump, Sanitary Blender

Reference: SV-18H

Solid Inlet Sizes: 3"-4" (DN80-DN100)

Liquid Inlet Sizes: 1 1/2"-2 1/2" (DN40-DN65)

Outlet Sizes: 2"-3" (DN50-DN80)

End connections: tri-clamp, thread

Body Material: AISI 304 (1.4301), AISI 316L (1.4404)

Mechanisal Seal: SIC/SIC/EPDM, C/SIC/EPDM

Power Supply: 3KW-15KW

Voltage: AC110V, 220V, 380V

Maximum temperature: 120℃/248°F

Surface treatment: Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default.

INQUIRY

Solid Inlet Sizes: 3"-4" (DN80-DN100)

Liquid Inlet Sizes: 1 1/2"-2 1/2" (DN40-DN65)

Outlet Sizes: 2"-3" (DN50-DN80)

End connections: tri-clamp, thread

Body Material: AISI 304 (1.4301), AISI 316L (1.4404)

Mechanisal Seal: SIC/SIC/EPDM, C/SIC/EPDM

Power Supply: 3KW-15KW

Voltage: AC110V, 220V, 380V

Maximum temperature: 120℃/248°F

Surface treatment: Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default.

APPLICATION

SV-18H series Sanitary Mixing Pump is used to mix solids in liquids. In food-processing industry, they provide a perfect solution for reconstituting powdered milk, making syrups, preparing brines, etc. It can also be a solution for preparing solid-liquid mixtures in the pharmaceutical, cosmetics and chemical industries.

TECHNICAL DATA

| Solid Inlet Sizes | 3″-4″ (DN80-DN100) |

| Liquid Inlet Sizes | 1 1/2″-2 1/2″ (DN40-DN65) |

| Outlet Sizes | 2″-3″ (DN50-DN80) |

| End Connections | tri-clamp, thread |

| Body Material | AISI 304 (1.4301), AISI 316L (1.4404) |

| Mechanisal Seal | SIC/SIC/EPDM, C/SIC/EPDM |

| Power Supply | 3KW-15KW |

| Voltage | AC110V, 220V, 380V |

| Maximum temperature | 120℃/248°F |

| Internal Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default. |

| External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm), Ra 32µin as default. |

DESIGN FEATURES

● Simple and versatile assembly for quick and homogeneous mixing of a great variety of solids without contact with the air

● 3A sanitary design.

● Easy assembly and disassembly by clamp connections

● Cleaning can be carried out without disassemblingthe unit.

● Sanitary single mechanical seal, double mechanical seal with cooling system as option.

● 60°Hopper

● Screen in the mixing chamber

● Drainage